Topics

Converting a crisis into an opportunity – three ways that a Smarter Supply Chain offers resilience

24 March, 2021 | Written by: Tom Woodham

Categorized: Perspectives | Topics

Share this post:

Converting a crisis into an opportunity – three ways that a Smarter Supply Chain offers resilience

The past 12 months has tested the worlds’ supply chains, exposing critical vulnerabilities and the painful truth that many companies have limited visibility of their supply chains, while only a small number actually have visibility into production.

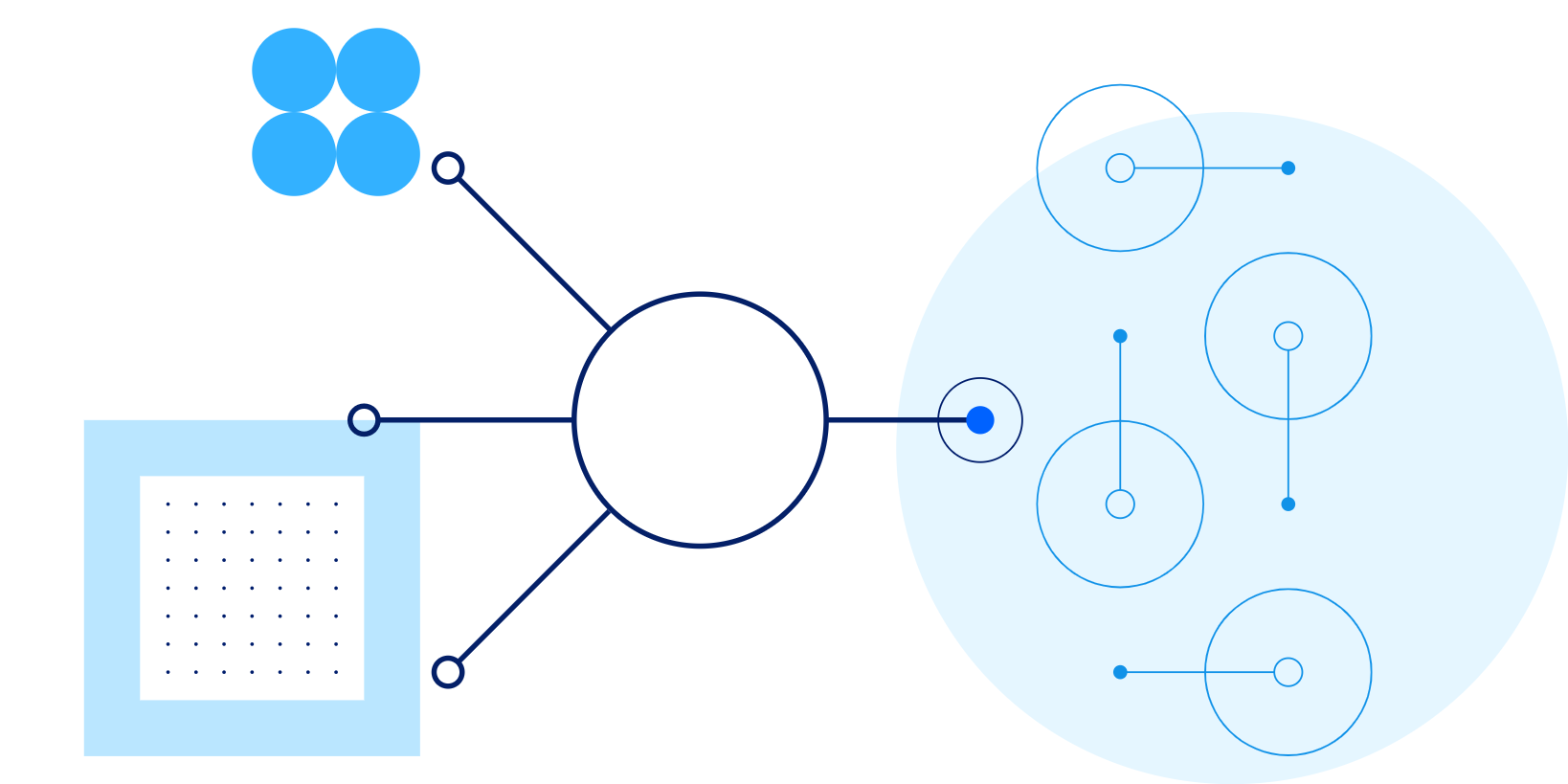

Operational resilience is built on data and supply chains must move beyond visibility to predict and rapidly act on data. This requires a platform for information sharing across organisational boundaries, creating supply chains that are dynamic, responsive and interconnected.

Digital resilience comes from Smarter Supply Chains; systems based on exponential technologies can help organisations build smarter supply chains and increase digital resilience. Smarter supply chains leveraging the power of AI and other emerging technologies help companies maintain business continuity amid disruption and uncertainty.

Organisations who are digitally resilient are able to flex and adapt supply chains and have successfully navigated the COVID-19 crisis, every sector has companies that have converted crisis into opportunity: retailers who rapidly pivoted to online for home delivery and click and collect grew market share, manufacturers who adapted their supply base for sourcing of materials during lockdowns, acquired new customers. The key learning is those who invested in digital and physical resilience of their supply chains turned a crisis into an opportunity.

We must seize this opportunity to act on the lessons of the pandemic, building on supply chain visibility, resilience and risk to re-imagine our supply chains for the future.

By reimagining supply chain processes into intelligent workflows, organisations can achieve new levels of responsiveness and resilience. Intelligent workflows challenge siloed processes and ways of working to uncover efficiencies across a network of processes and partners.

Augmented by AI and technologies like automation, blockchain, IoT, 5G and edge computing, supply chain intelligent workflows deliver exceptional outcomes – at scale. All steps in the value chain can be transformed; from demand planning, manufacturing execution, order orchestration and fulfilment. Intelligent workflows reimagine the intersection of people, process and technology, enabling supply chain professionals to deliver more effectively against changing strategies and environments.

Transformation is Achieved on Three Levels

To build resiliency, agility and predictability, supply chain workflows are transformed over three levels – a smarter supply chain is able to see, predict and act to navigate disruption.

Smarter Supply Chains ‘See’, using AI to leverage unstructured real-time data provides near-term visibility and insights. A global tool, like Sterling Control Tower, offers end to end visibility of supply chain flows; combining this with the IBM Hyper Insights blockchain solution then allows you to see where your products are, in real-time, across the world. Feeding data like shipping transit data, directly into a Control Tower, converts previously unused data into valuable information – a quick win. Covid-19 may have prompted your team to try to manually improve visibility – over time you can start to automate these processes, scaling them across the enterprise and ultimately providing highly personalised data for actionable insights.

Smarter Supply Chains ‘Predict’: for true responsiveness, data must be forward looking, predicting what will happen next, however, supply chain planning often uses historical data and seasonal patterns, resulting in poor predictions in a fast-changing world … A new approach combines continuous intelligent planning with real-time collaboration, across the organisation and supply chain. Never before has it been so important to use real-time data to anticipate consumer behaviour or external disruptions – companies using demand sensing for structured, unstructured and dark data during the pandemic have reacted quicker, mobilising resources where needed – for example, spotting weeks in advance a raw material shortage and immediately taking evasive action.

BASF is benefitting from AI to manage their supply chain and predict potential disruptions.

Smarter Supply Chains ‘Act’: using intelligent workflows to predict what needs to be done, based on AI and scenario planning, developing resilience from built-in flexibility and agility. Collaboration rooms and data sharing platforms bring together strategic partners to act on disruption across supply chains – leading to faster decisions, responses and resolutions. Machines today constantly analyse and develop hypotheses based on all data, allowing the supply chain professional, to perform rapid scenario planning to determine options and outrun the competition.

The IBM Systems supply chain, has cognitive control tower capabilities to identify early warnings using external data e.g. social media and The Weather Company insights. Supply chain professionals quickly act on information, freeing more time to focus on higher value activities like customer and supplier communications. Watson AI allows our professionals to optimise orders based on criticality and IBM teams react speedily, eliminating time spent collecting data to focus on higher value work.

Using experience, our advanced cognitive supply chain, world-leading data, cloud and blockchain capabilities, and experience-led methodology, we are perfectly positioned to help clients transform their supply chains, driving resiliency, agility and predictability. Now is the perfect moment to build a smarter supply chain, levering AI, automation and blockchain, delivered through cloud-based applications.

Summary

- Visibility is created across your end-to-end supply chain with a Cloud based platform or control tower sharing and collecting data for smarter, aligned organisation benefitting from re-imagined Intelligent Workflows replacing manual aggregation and accelerating decision making.

- Predict using smarter supply chain modelling and scenario analysis for immediate assessment and longer-term ability to continually evaluate the balance of lean operations and risk mitigation.

- Act using systems for digital resilience by allowing strategic partners to quickly collaborate and understand the impact of disruptions. Leverage AI to support rapid scenario planning and unlock hidden insights to determine options and take action.

Visit our web site for an interactive demo and see how IBM can help you improve your supply chain.

Partner, IBM Global Business Services, Cognitive Process Re-Engineering Supply Chain & Procurement Leader, UK&I

Generative AI: driving a new era of HR transformation

Helen Gowler, Partner, EMEA Talent & Transformation Lead Today, I’m proud to be part of a company that’s committed to addressing gender bias in the tech industry. IBM is pioneering the use of AI to tackle this issue, and I’m excited to contribute to this effort. Our team is developing AI models that can detect […]

Multi-Modal Intelligence Platform

Traditionally, data management systems provided only numerical or textual based business intelligence primarily for back-office users across finance, sales, customer management and supply chain. Today, we are increasingly seeing data management systems which drive key business functions requiring interrogation of multi-modal data sets from documents, presentations, images, videos to audio. This demands a more sophisticated […]

The use of GenAI to Migrate and Modernise Organisational Core Programming Languages

GenAI is hugely powerful and supports a diversity of use cases by focusing on routine work – allowing people to focus time on value-add tasks, thus enhancing productivity. The focus of this use case is for an organisation which had previously focussed on a legacy set of tooling and programming languages and needed a way […]