About cookies on this site Our websites require some cookies to function properly (required). In addition, other cookies may be used with your consent to analyze site usage, improve the user experience and for advertising. For more information, please review your options. By visiting our website, you agree to our processing of information as described in IBM’sprivacy statement. To provide a smooth navigation, your cookie preferences will be shared across the IBM web domains listed here.

Perspectives

IBM employees join the rallying call to build visors for NHS staff

9 April, 2020 | Written by: Andy Stanford-Clark

Categorized: Perspectives

Share this post:

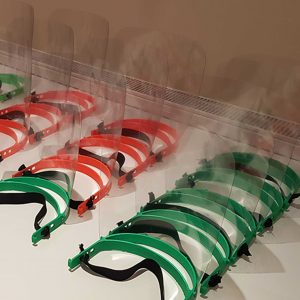

IBM staff with 3D printers are volunteering to turn their devices and skills to help alleviate the shortage of protective face visors for hospitals. Within just the first few days of a rallying call for help, a shipment of 20 visors was created and sent to a grateful University Hospital Southampton.

Over 300 have now been distributed, and many more are in production as the team grows and gets more printers running, in what has become a virtual assembly line across the team’s homes. Requests have now been received from around the country including London, Manchester, Birmingham and Bristol. The initiative has even been recognised by the Member of Parliament for Harrow West, Gareth Thomas.

How it all started

One of last year’s interns at IBM Hursley, Dhiresh Nathwani, contacted Developer Advocate, Sean Tracey, and me to let us know about face visors that can be created by anyone with a 3D printer, and which are designed to help protect medical professionals who are treating patients affected by COVID-19.

Sean immediately set his printer into action to test the open source model and after 2 hours of printing, some acetate cutting, and attaching a rubber band, he had created his first protective visor. I also printed a sample visor on my 3D printer at home. The sense of accomplishment and realisation that we’d be able to help people desperately in need of supplies led to the start of our collaboration with Dhiresh, and a search for other ’makers’ to join the effort.

The rallying call

So now we were three, but I knew we needed more people if we were going to be able to produce the quantities required to make a real difference. We put a call out to friends and colleagues in the technical community, reasoning that they would be the most likely to have access to 3D printers. The immediate response was amazing, and the message spread rapidly by word of mouth. By the end of the following day, the team of volunteers had grown to over 20 people, made up of both IBMers primarily linked to the Hursley lab near Winchester, and makers out in the wider community from London and the South East.

How useful are 3D printed masks?

The masks are intended to help prevent fluids from patients coming into contact with the skin of hospital staff. In normal circumstances healthcare professionals would have acc

ess to medically certified visors to provide the necessary protection, but these are not normal circumstances. These home-made visors are not medically approved or tested devices, and they are produced and supplied through a volunteering initiative, not on any commercial basis. They are intended and acknowledged as a temporary measure to try and help keep frontline staff safer than if they had no protection at all. Each mask is typically used for one shift although some hospitals are exploring the possibility of cleaning them for re-use.

Progress update

Since the team started production on 26th March, we have received requests for nearly 2,000 visors from more than 20 NHS trusts and health services across the country. On the 31st March we shipped the first batch to University Hospital Southampton where they’ve been put straight into service. On Sunday 5th April the team sent out a further 100 visors and now more than 300 have been distributed.

Angie McClarren, Service Improvement Manager, University Hospital Southampton sent us her appreciation: “Thanks for the delivery – everyone loved them and we are trying them out now. I have attached a photo of one of our sisters modelling the mask for you.”

How are the masks made and funded?

Each visor consists of 3 components: a 3D printed frame which holds a sheet of acetate and an elastic strap. Once the plastic frame has finished printing, the sheet of acetate has holes punched into it and the two are fixed together by clipping the acetate over pegs on the frame. Finally, the elastic strap is secured over hooks at the back of the frame. Each mask costs about £2.50 in materials to produce, and can be ready to go in 2 hours.

Originally most of us were using our own supplies but it was quickly recognised that a longer-term solution was needed, especially to help those who currently find themselves in a difficult financial situation. To fund production, Dhiresh and fellow maker from the community, Abhi Patel, turned to crowd-funding through GoFundMe which reached its initial goal of £3,500 in less than 5 hours, by the 31st March an additional £2,500 had been donated. This generosity has enabled the team to buy additional filament, acetate and more printers to help in the effort. Initially we had the capacity to produce approximately a dozen masks per day, but we now have capacity for more than 120, with additional printers volunteering to join the team every day.

Upon hearing of the GoFundMe, Gareth Thomas – Labour & Co-operative MP for Harrow West tweeted his thanks for the team’s efforts, “Impressive stuff – thank you for what you’re

doing – it matters.”

Sean, who is currently volunteering full-time on the project, is already looking to the future: “When this crisis is over, these additional printers will be donated to local schools so that the next generation of makers will have a head start in using 3D printing technology to solve problems.”

Want to get involved?

While it’s incredible to have gone from an idea to a distributed assembly line in less than a week, we need more help and there are ways in which others can get involved.

1. If you have access to a 3D printer. Everything needed to help make more masks is documented here: https://github.com/seanmtracey/PPE-Visor-Fabrication-Instructions

2. If you’d like to make a donation. This project is being run on a voluntary basis and contributions towards acquiring the materials used to manufacture the masks can be m

ade here: https://www.gofundme.com/f/3d-printed-visors-for-the-nhs. Any excess funds raised will be donated to charities, selected by the volunteers once production of the visors ends.

3. People with suggestions or other offers of help can get in contact with the team at: makers4thenhs@gmail.com

Andy Stanford-Clark

IBM CTO - UK and Ireland. Distinguished Engineer. Master Inventor

More Perspectives stories

By Col Chambers and Ed Gillett on 5 February, 2025

Preparing for the defence of the Realm

In light of current conflicts, the UK is now faced with real-world military decisions that will affect our immediate future. Ed Gillett and Col Chambers assert that industry and government must switch to a readiness mindset before the European post-war peace shatters. “My vision for the British Army is to field fifth-generation land […]

By Juan Bernabe Moreno and others on 12 December, 2024

Frontier Fusion: Accelerating the Path to Net Zero with Next Generation Innovation

Delivering the world’s first fusion powerplants has long been referred to as a grand challenge – requiring international collaboration across a broad range of technical disciplines at the forefront of science and engineering. To recreate a star here on Earth requires a complex piece of engineering called a “tokamak” essentially, a “magnetic bottle”. Our […]

By Nick Levy on 9 December, 2024

Safer Technology Change in the Financial Services Industry

Many thanks to Benita Kailey for their review feedback and contributions to this blog. Safe change is critical in keeping the trust of customers, protecting a bank’s brand, and maintaining compliance with regulatory requirements. The pace of change is never going to be this slow again. The pace of technology innovation, business […]