About cookies on this site Our websites require some cookies to function properly (required). In addition, other cookies may be used with your consent to analyze site usage, improve the user experience and for advertising. For more information, please review your options. By visiting our website, you agree to our processing of information as described in IBM’sprivacy statement. To provide a smooth navigation, your cookie preferences will be shared across the IBM web domains listed here.

Aerospace and Defence

Manufacturing 4.0 meets Defence 4.0

15 December, 2021 | Written by: Richard Davies

Categorized: Aerospace and Defence

Share this post:

The UK Manufacturing industry is in the midst of a transformation, often termed ‘Manufacturing 4.0’, which is enabled by the seamless digital management of assets through a life cycle, from product concept and design to manufacturing through to operations and retirement. Defence is on the cusp of an even bolder transformation, headlined in the UK as Multi Domain Integration (MDI), which integrates data from multiple sources including assets/devices, sensors, process and intelligence to provide a complete cross-domain picture of readiness and operations supported by analytical modelling and simulation to support integrated Command and Control (C2); this is sometimes termed ‘Defence 4.0’.

In this brief paper, these two ‘paradigm’ shifts are explored and it is proposed that they will, and need to be, increasingly entwined, but to a ‘Framework’ orchestrated by Defence.

What is Manufacturing 4.0?

Manufacturing 4.0 might be characterised as follows:

- A shift from producing hardware intensive assets to more complex software intensive/differentiated assets, akin to a Tesla car (as discussed in a previous blog – ‘Defence Data – A New Strategic Asset’),

- The use of data to drive the seamless management of an asset from the origin of a collaborative design process right through to the operation and support of that asset (i.e. to Maintenance, Repair and Overhaul – MRO),

- The creation, maintenance and flow of a ‘Digital Thread’ through the full asset life cycle so that, for example, a part which repeatedly fails in service can be tracked back in the system to its design and can consequently be redesigned quickly and effectively,

- Enablement of a Digital Twin that creates a digital mirror of the physical design, using algorithms, that enables modelling and testing of designs in a virtual world speeding development times,

- Rapid adoption and realisation of value from new exponential technologies through agile, iterative development and ‘test and learn’ using prototyping,

- Leverage of a diverse collaborative ecosystem from industry and academia to drive value from collaborative innovation,

- Co-creation of user centric solutions e.g using IBM’s ‘Design Thinking’ methodology with a focus on persona journeys and ‘experience’ to inform the development of products/solutions which links to agile delivery in IBM’s ‘Garage’ approach,

- Leveraging new digital engineering skills and associated tooling.

What is Defence 4.0

Defence 4.0 can be characterised by the following features:

- Flexible physical asset platforms that can be rapidly configured, using software, to meet dynamic threats,

- A ‘network of networks’ of multiple assets with sensors combined with other data sources to support intelligent AI enabled planning and operational MDI enabled decision-making,

- Supported by a ‘Digital Backbone’ that is ‘Singular’ – delivered by a cohesive and qualified workforce on common architecture, ‘Secure’ – protected networks, systems and decisions, ‘Modern’ – Cloud based and incorporating modern technologies, ‘Digital’ – enabling the exploitation of data and software (1),

- Horizonal intelligent workflows, supporting end-to-end asset management and operations by cutting across functional/asset domains and organisational silos,

- Ubiquitous data driving decision making,

- Analytics and AI enabled Command & Control (C2) decision-making at the hub with processing at the edge (i.e. independent processing within assets or groups of assets) to add dynamism and resilience,

- Assets optimised with intelligent/predictive analysis e.g. predictive maintenance in MRO,

- The mirroring of the physical asset, or asset networks, using a virtual algorithmic model, or Digital Twin, to inform design and operational decisions, through simulation for example,

- New digital skills and agile ways of working for cohesive, agile centric, MDI operations.

The Convergence of Manufacturing 4.0 and Defence 4.0

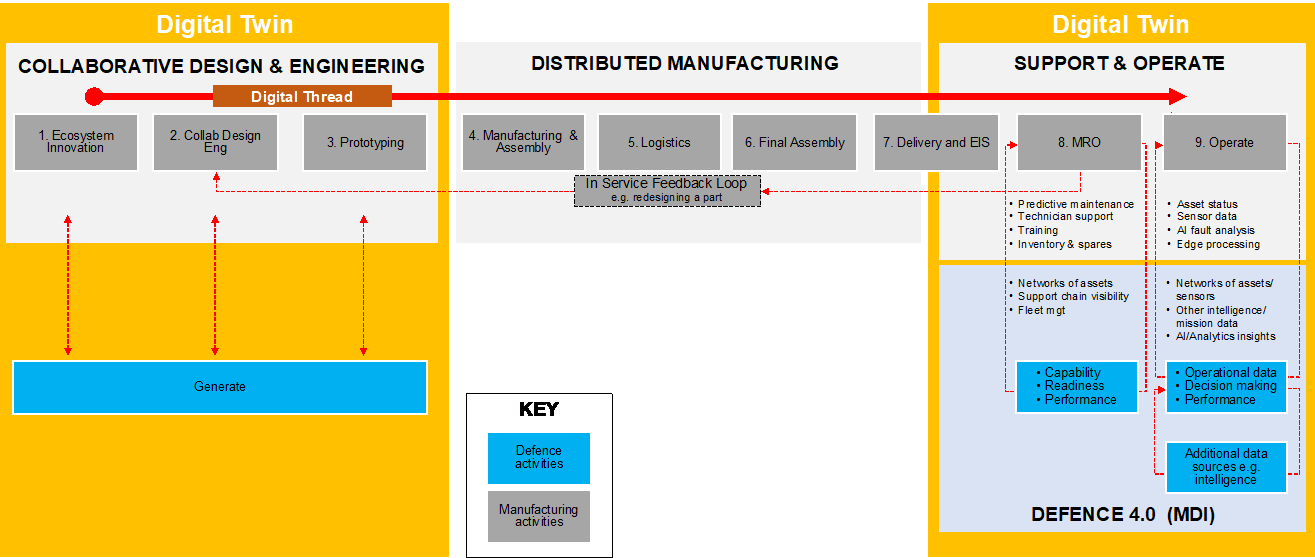

Manufacturing 4.0 and Defence 4.0 come together in ‘Digital Engineering Service, Support & Operate’ that is presented in Figure 1 which shows the end-to-end life cycle from left to right. The Digital Thread sits across that cycle, linking the elements to support a workflow.

Figure 1. Summary of End-to-end Digital Engineering Service, Support & Operate

The convergence of Manufacturing 4.0 and Defence 4.0 is explored in more detail below through the lenses of ‘Collaborative Design & Engineering’ and ‘Support & Operate’:

Collaborative Design & Engineering in 4.0

a) From the manufacturer’s perspective:

- A design platform that is integrated between an ecosystem of partners to enable coordinated collaboration,

- The ability to cost effectively simulate designs in a virtual world, ultimately using a Digital Twin,

- An approach that drives ‘test and learn’ prototyping, again ultimately in a Digital Twin.

b) From the Defence organisation’s perspective:

- To shape and engage in the innovation and design process through the duration of the product life cycle.

‘Support & Operate’ in 4.0

Maintenance, Repair and Overhaul

a) From the manufacturer’s perspective:

- The manufacturer, the in-service support provider and the Defence organisation are integrated in a single virtual system for key activities,

- Ability to leverage an ecosystem of innovative capabilities from multiple partners,

- The use of digital to deliver key capabilities and processes, for instance, predictive maintenance (e.g. using AI and analytics), technician support (in line with latest product status),

- Provision of digital training for technicians and engineers (e.g. using augmented reality),

- Analytics enabled insights and decisions on spares inventory and logistics with integration to order management.

b) From the Defence organisation’s perspective:

- The current status of all assets is known,

- The status of the supply chain is transparent e.g. visibility that a part has been ordered and can be tracked,

- A fleet of assets can be managed in the round.

Operate

a) From the manufacturer’s perspective:

- A digital picture of the status of individual and integrated assets,

- Insights from sensors on the platforms informing MRO decisions,

- AI enabled fault analysis (e.g. a part overheating which AI suggests is a symptom from something else which triggers a workflow event via the ‘In Service Feedback Loop’ to the ecosystem for an innovative resolution),

- Edge processing enables individual assets, or clusters of assets, to utilise independent processing which adds resilience.

b) From the Defence organisation’s perspective:

- All assets and their status are visible, including data from sensor/sensors which can be modelled or simulated,

- Additional intelligence and mission data can be aggregated and analysed to support better decisions (e.g. by applying AI and analytics),

- Performance can be managed using timely data (e.g. near real-time data if appropriate),

- Data and insight on for example: capacity, status, capability, location and intelligence to inform a single joined-up operational picture.

The Evolution of Digital Twin

Digital Twin is maturing quickly, perhaps most visibly in Formula 1 where in-car sensors, track side decisions and a supporting hub are considered ‘business as usual’.

Two Digital Twins are illustrated in Figure 1 above. Firstly, one showing a mirrored view of ‘Support & Operate’ where full operational capability and scenarios can be modelled. An example of this is where levels of readiness can be managed by utilising scenarios and evidence-based status reports.

Secondly in Figure 1, a ‘Collaborative Design & Engineering’ Digital Twin is shown where the manufacturing ecosystem develops solutions collaboratively and tests concepts in a virtual model rather than, the much more expensive, physical world.

The Digital Twin could represent individual vertical domains; not limited to the two illustrated in Figure 1. Building incrementally over time, the Digital Twin can leverage the Digital Twin to deliver full horizontal coverage and can progressively link verticals to cover an increasing number of assets.

Sustainability 4.0 – Sustainability by Design

Sustainability is of critical importance and the challenge is to reduce emissions now and then drive improvements forward in the coming decades; so it’s key. The solution set described above represents a significant opportunity to deliver important sustainability benefits, especially if designed in early. The full digital engineering services lifecycle offers the ability to measure and manage the sustainability of the ecosystem and their products with the Digital Twin supporting the provenance and decisions. This includes designing platforms from first principles with retirement and decommissioning in mind. This would lead to assets being developed in a ‘Sustainable by Design’ way, utilising ecosystem collaboration. Further, the comprehensive nature of the converged model means resources and emissions can be optimised, particularly in the Support and Operate space in Figure 1.

It is increasingly true that Sustainability is not only about decarbonization, it is also about creating business models, building a skills base and designing products and services for a long term, sustainable future.

Developing an Enterprise Design Framework is key

Vertical asset domains can be matured in an iterative manner, especially as new assets are developed (e.g. the Tempest project in the UK) and ultimately joined horizontally with workflows and Digital Twins to realise MDI. It is critical that all development and change complies to a single, managed, future proofed ‘Framework’ and associated operating model. The Framework should cover standardised components and design principles covering: infrastructure, security, applications, data models and workflows; plus an Operating Model and ways of working. This Framework should be led and orchestrated by Defence because they need capability and designs that glue everything together in a cohesive, future proofed, MDI enabling way. Vitally, this framework must be: flexible to meet emerging needs including those from a dynamic ecosystem, scalable to meet enterprise needs, and reusable so it can be deployed across differing asset classes as it is iteratively developed into a single MDI solution with a comprehensive Digital Twin.

Key challenges in making convergence happen

In manufacturing these challenges include:

- The ability to manage increasing complexity of physical hardware combined with software,

- Reducing the high cost of production, exacerbated by: increasing asset complexity, development time/effort, waste, rework, and quality issues,

- Overcoming the siloed development of R&D activities slowing and inhibiting innovation,

- Successfully coordinating and integrating a diverse ecosystem of partners (large and small),

- Successfully managing the commercials (including IPR) in an ecosystem,

- Integrating different solutions across brown field sites within the ecosystem,

- Making the right strategic investment decisions around new digital manufacturing technologies,

- Operating collaborative platforms that are secure,

- Fixing process disconnects and pain points in the value chain e.g. linking complex collaborative design to manufacture.

For Defence, challenges include:

- Making a bold MDI vision, written in Strategy papers, a practical reality; linking MDI, asset management and Digital Engineering in a cohesive solution,

- Managing the high and increasing cost of developing, operating and maintaining new complex software intensive assets and understanding value,

- Reducing siloed operations and processes adding cost and creating operational issues,

- Adopting a technical solution that integrates with an ecosystem but which is secure. The cost differential of creating and running a secure cloud is significant, so establishing a core design, with secure only where you need it, is key,

- Determining the right business/operating model (e.g. Lead SI and ecosystem) for a Digital Engineering ecosystem,

- Developing a new operating model with the right digital skills and collaborative behaviours that align with industry,

- Helping manufacturing develop the right model that meets integrated, coordinated, enterprise needs.

Summary

- Digital Engineering is transformational for both Defence organisations and manufacturing industry,

- Success will be about getting the most out of the data from the end-to-end cycle in Figure 1,

- The future state, with integrated operations including Digital Twin, will take decades to build, but a Framework, and Operating Model driven by Defence, needs to be established early and matured collaboratively within Defence and with industry,

- Sustainability can be designed into the solution impacting all ecosystem players and the full Digital Engineering life cycle,

- The complexity of building an ecosystem needs to be addressed. Realistically this will mean integrating brown field sites and managing complex security requirements,

- This is as much a cultural challenge as it is a technical one; as collaborative (agile) working, is likely to represent huge challenges in both Defence and manufacturing industry,

- Fundamentally, a cohesive vision is required, which is supported by a design Framework to meet enterprise Defence needs. However, the response should not be a library of requirements (see previous blog – Digital Transformation in Defence – Balancing the Strategic and the Tactical). The strategy and framework need to be deployed in an agile manner.

Call to Action

The imperative is for Defence to determine a converged 4.0 strategy and then articulate and design an MDI enabled Framework for assets. This Framework will be an evolving Platform that will ultimately realise Digital Twin. The design for the Framework must be established quickly, with suitable governance, so that it can be accommodated in the development of new assets, like Tempest, whilst providing a blueprint for the transformation of legacy. The Framework must be developed in collaboration with industry and should be designed once and built once and then iterated; it must not be reinvented for every asset.

(1) Digital Strategy for Defence – Delivering the Digital Backbone and unleashing the power of Defence’s data, UK Ministry of Defence, April 2021

————————————————————————————————————————-

Richard Davies

Enterprise Strategy - Defence Lead IBM

More Aerospace and Defence stories

By Col Chambers and Ed Gillett on 5 February, 2025

Preparing for the defence of the Realm

In light of current conflicts, the UK is now faced with real-world military decisions that will affect our immediate future. Ed Gillett and Col Chambers assert that industry and government must switch to a readiness mindset before the European post-war peace shatters. “My vision for the British Army is to field fifth-generation land […]